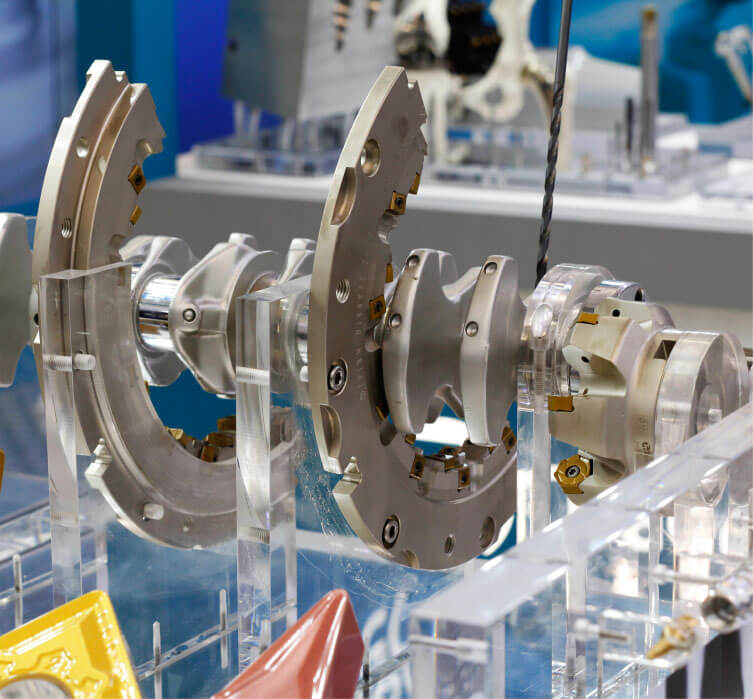

Cutters

About the Metalbud Cutter’s

NOWICKI Cutters Australia

Cutters – Stainless steel construction

- High quality and repeatability of stuffing production

- Optimal shape of the cutting chamber in combination with the shape of the knives

- Equal stuff crumbling in all the bowl’s volume caused by “cutting in the air”

- High-speed rotations of knife head (cutting rotations)

- Microprocessor control system

- Smooth control of cutting and mixing rotations as a standard

- Possibility of programming up to 40 technological programs

- Automatic water dosage system

- Effective noise insulation cover

- Head with cutting knives not requiring regulation of distance from bowl

- Stuffing temperature control

- Automatic central lubrication system

- Possibility to install a higher power motor for heavy stuffing production

- Hydraulic loading to production trolleys 200 l

- Easy unloading with the stuffing unloader controlled by a joystick

- Hydraulically operated front and back covers of the bowl

- Monitoring system of the current machine operation, auto diagnostic and sound signaling system

- Construction meets the highest hygiene requirements (flat surfaces inclined at an angle of 3 degrees)

- Product contact surfaces are polished

- Complete work safety system